1 Bit TIFF encapsulated data into PDF for Flexo24 plates

1 Bit TIFF encapsulated data into PDF for Flexo24 plates

1 Bit TIFF is the basic encoding of the graphic elements encapsulated in the PDF file. Such encoding must be set correctly as it disinhibits all the information set by our Flexo 24 configurator. Only for professionals in the flexographic prepress.

Flexo 24 is online, agile service for the flexo industry, read this article, the next step in innovation is already here: it is the 1-bit TIFF, called “LEN file” by Esko, the leading company for flexo software and hardware.

PRO TIP

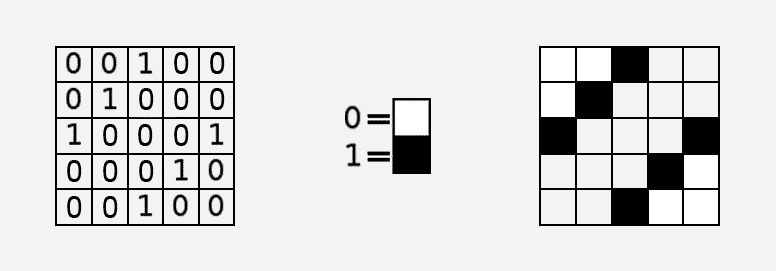

1-bit TIFF is the file format that:

• describes an image in the binary code. This file is suitable to image the plates directly from the RIP with Flexo 24’s technology.

• essential decodification, which is transferred to the laser for the ablation of the digital flexo plate.

ESKO IMAGING, the RIP from Esko.

Once the PDF file is uploaded in the configurator, all the graphic elements are read by the RIP.

1-bit TIFF or Esko LEN are formats that represent the image’s pixels (the elements to engrave on the plates) in the binary code, with 2 information only: on/off. These files are generated by a RIP and used for the imaging of flexo plates.

PRO TIP

The Raster Image Processor (RIP) analyses the PDF file and generates the encapsulated file for a direct transfer to ESKO’s ablation machines available in Flexo 24’s equipment. This file will be then reproduced on the plates.

What is the encapsulated 1 Bit TIFF?

These are files encapsulated inside the PDF:

- they are made up only from black and white information. They contain rastered graphic elements, with dot shape, angles and different compensation curves (DGC) that must be necessarily considered, and any other technology from the RIP that generated them.

- they can be considered as a digital “film”. Graphic elements and screened objects are reproduced on the digital flexo plates exactly as they are incorporated in the PDF file.

In order to be used with the Flexo 24 tools they:

- should be encapsulated in PDF files

- should be one file for each color separation

- should not be multi-page.

This file encoding must be set correctly, as it might disinhibit the options set in our Flexo 24 configurator while the order is being processed:

- screen ruling,

- engraving angle

- compensation curve (DGC).

Some parameters should always be set from the configurators::

- resolution (selected value in the configurator and set value in your RIP must be the same)

- printing direction: front or reverse.

PRO TIP

Default values of the RIP Imaging Engine are also disinhibited:

1) screened dots shape, preset as “circular”.

2) minimum bump-up value, essential to avoid smallest dots from dropping. This depends from type of substrate, substrate-ink combination and screen count.

Why using a 1-bit TIFF file?

The main benefit of using this format is that it enables Flexo 24 to image flexo plates with the RIP and the values from the customer’s printing system while:

- reducing time for realization of the PDF.

- granting an exact combination of the values from the customer’s printing system.

Encapsulated files should be managed by flexo pre-press professionals.

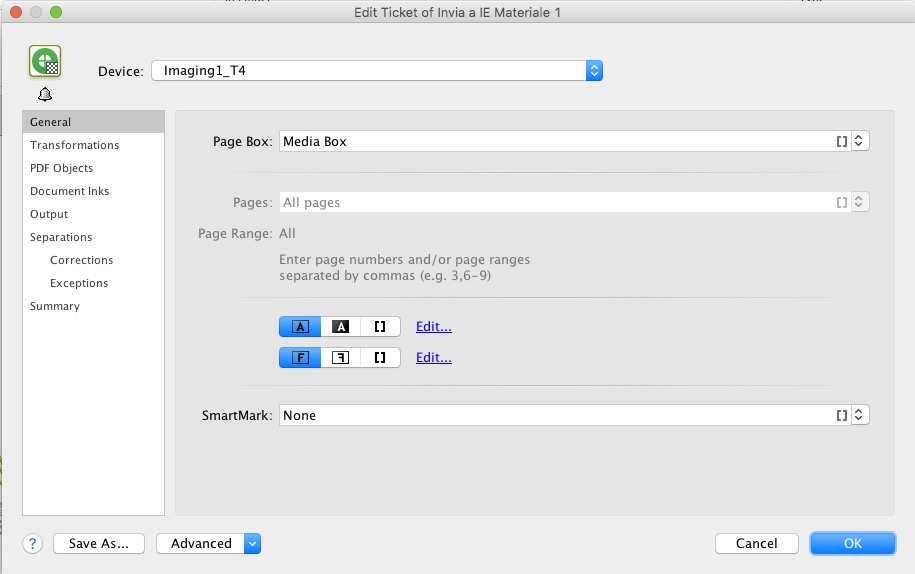

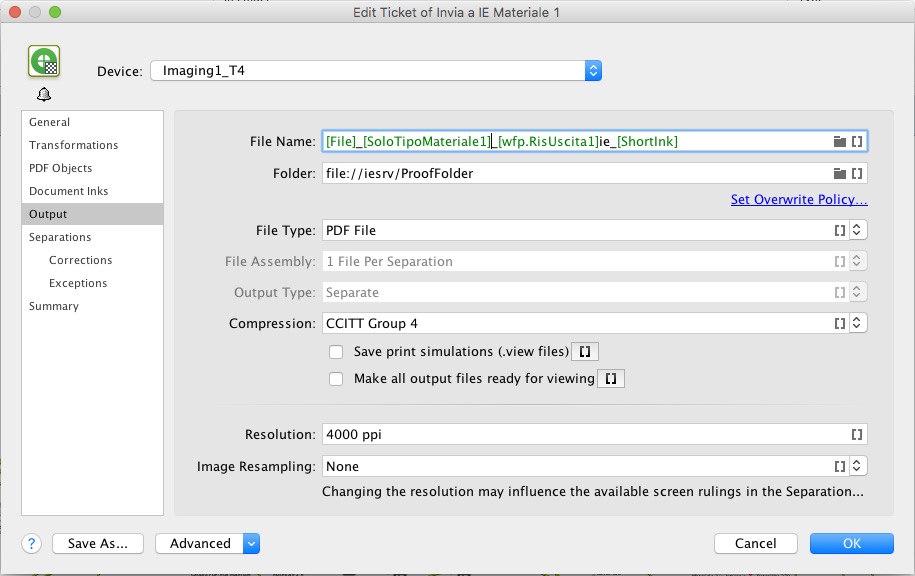

How to set Esko Imaging Engine to create files encapsulated in PDF?

Various RIP computer software are available to manage and create LEN files, Flexo 24 uses Esko Imaging Engine. This system is specific for flexo and generates the PDF file with 1-bit TIFF and LEN already encapsulated.

Here follow the instructions if you are using this RIP and want to generate a 1-bit TIFF or LEN encapsulated in PDF.

In case of other RIP systems, please check the matching featuresi.

PRO TIP

The PDF output features – compensation curves (DGC), dot shape, and others – are usually available in all the most advanced RIP systems, though some of these features may vary according to the companies that produce them. To set the correct parameters please contact your reference person

1. “Right reading” print.

Film or paper image should be read normally, from left to right and top to bottom, as we indicate here:

2. Output format.

Flexo 24 only accepts PDF files, so compression must be CCCIT4 with a maximum value.

3. Resolution.

In case of a plate with resolution 2540 or 4000 dpi, the value set in our Flexo 24 configurator must absolutely match the value that was set in Imaging Engine or in the RIP system.

PRO TIP

If the resolution value set in the 1-bit TIFF does not match the one you set in the configurator, some moiré patterns or strange effects may occur.

When uploading to the Flexo 24 system the 1-bit TIFF files encapsulated in PDF, all the features in the configurator, though they can be still selected, are dishinhibited:

- screen ruling,

- engraving angle,

- dot gain compensation curve (DGC) value,

- type of dot,

- bump-up value.

PRO TIP

Only print type (reverse/front) and resolution will be conserved. So when your file is generated, its settings must consider all the above mentioned parameters.

>> We suggest that the LEN files should be managed only by experts in the flexo pre-press field. <<

Advanced technology features for skilled professionals under their responsibility.

If you decide to use a file encapsulated in PDF, we remind you that you are responsible for:

- wrong bump-up values (small dots dropping),

- unsuitable DGC values,

- screened dots shape and angles not suitable for flexo,

- mismatch of the rastered file resolution encapsulated in PDF,

- resolution selected in the Flexo 24 configurator.

Flexo 24’s service is completely digital and adds new features to improve the quality of the technology offered to customers.