Flexo plate distortion: precaution for flexo printing.

Flexo plate distortion: precaution for flexo printing.

Flexo plate distortion: How to calculate it and get high quality flexographic printing?

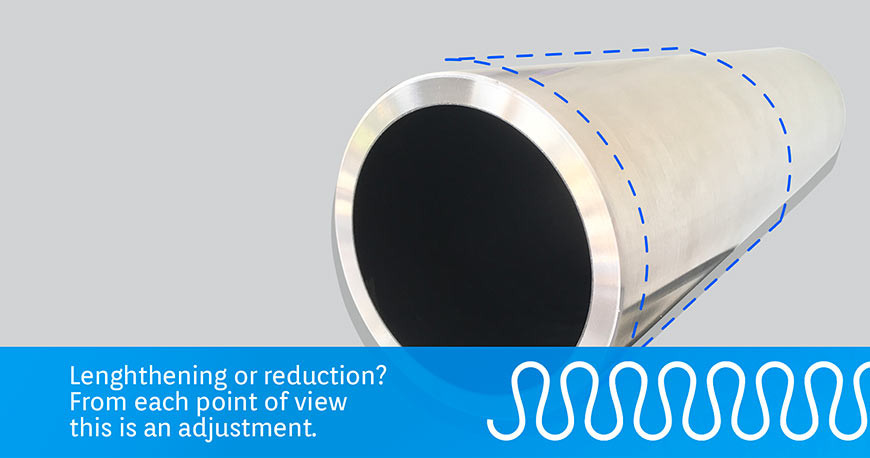

Most flexo digital plates are exposed on a flat surface.They’d print an exact copy of the negative if it was not for the fact they have to be wrapped around a cylinder for flexo printing. When the flexo rubber plates are mounted on these cylinders:

- Flexo machines print the longest image in the printing direction following the negative, causing flexographic elongation or distortion.

- The results do not match the desired ones, and the packaging or label printing are not satisfying.

PRO TIP

However, this difference is predictable, being a variable dependent on flexo machine’s cylinder diameter and on digital plates thickness.

Images must be reduced in the printing direction and with the table for calculating the flexo plate distortion it is possible to do it quickly, following a few and intuitive steps.

Buy now flexo readymade plates.

ORDER NOW THE FLEXO PRINTING PLATES, THE PHOTOPOLYMER FOR FLEXO PRINTING.

How to get photopolymer plates for flexography?

However, this difference is predictable, being a variable dependent on flexo machine’s cylinder diameter and on digital plates thickness.

Images must be reduced in the printing direction and with the table for calculating the flexo plate distortion it is possible to do it quickly, following a few and intuitive steps.

The guide to using flexo plate distortion calculator.

How to calculate flexo plate distortion?

Before loading the PDF for the realization of your digital plate with Flexo 24, you can calculate the negative distortion to apply to the file, by filling out the form you will find below. Follow these practical instructions:

- Choose the unit of measurement.

- Enter the value of the printing cylinder circumference.

- Select the thickness of the digital plate you want to realize.

- You immediately get the results in the table for calculating the flexo plate distortion.

- Apply the reduction to the graphics of your file using graphic softwares..

|

1) |

Choose the unit of measurement. |

|

|

2) |

Enter the value of the |

|

|

3) |

Select the thickness of the digital plate |

|

|

4) Get the results: You can view in the table for calculating the flexo plate distortion immediately. |

||

| This is the K constant. You need to reduce the step-print of your graphics: |

... mm |

|

| So your graphics must be deformed (in the printing direction) and brought to the step-print: |

... |

|

| Or if you prefer to use percentage, then you must deform (in the printing direction) your graphics: |

... |

|

Flexographic tutorial: learn more about with Flexo 24 Web Series.

Need a help for your flexo prepress? Here a tutorial about the management of the PDF file with the application of the reduction. Visit our Youtube channel for more useful videos.

Start now and become a Flexo 24 customer: create your own plate!